CIPP Trenchless Pipe Repair

Charles H. Call, Jr., P.E. Chief Engineer, Salt Lake City Department of Public Utilities

April 24, 2006

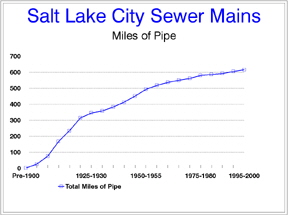

NEED

|

SOLUTION

The sewer system consists of vitrified clay, concrete and brick pipes. PU looked at new construction methods that would provide a long-term, cost-effective solution and at the same time minimize inconvenience to the public. The cured-in-place-pipe (CIPP) process was selected. This pipe rehabilitation method provides a structurally sound pipe that is also resistant to the corrosive environment that exists in sewerlines.

METHOD

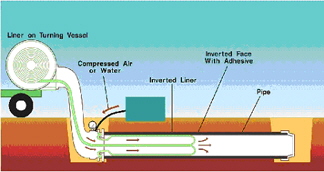

The CIPP process uses custom-manufactured felt tubes that are impregnated with a polyester thermosetting resin. The tubes are inserted into the damaged section of the pipe, usually through an existing manhole. Water pressure or steam is used to propel the tube through the pipe, turning the tube inside out while pressing it outward against the walls of the existing pipe. This is like pushing the end of a sock until it is “inside out” or inverted (Figure 2). When the tube reaches a termination point, the water or steam inside the tube is heated causing the resin to cure and harden. The result is a sturdy, jointless new pipe within the old pipe. Once in place, the robotic cutter cuts through the wall of the new pipe, reinstating the service connections

To verify successful completion, video cameras are used and the City inspects the work throughout the course of the project.

BENIFITS

This process results in significant savings. When compared to a conventional open-cut pipe replacement, the cost per foot for CIPP has been about one-forth the cost of replacing the pipe. In addition to cost savings,

|

The rehabilitated pipe is both sturdy and efficient. This process restores the original life to the pipe for less cost. This saves the cost of digging and service line rerouting. This trenchless alternative minimizes damage to existing pavement and reduces long-term street repair costs.

The sewer rehabilitation also has a number of positive environmental effects. Exfiltration from cracks in the old sewer lines can contaminate groundwater. Water flowing into the pipe through the leaks also erodes the surrounding soil. Sealing leaks helps maintain the soil support for the pipe. Also, the reduced flow in the sewers means that PU doesn't have to treat that extra water at its wastewater treatment plant.

|

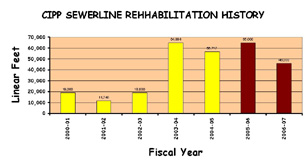

The CIPP design work is managed by Rick Reinhold. His design and inspection team members are John Miller, Steve Pack, Blaine Raby and James McDonald. PU used CIPP methods in the 1980’s but in about 2000 we started a more aggressive use (Figure 3). The last few years PU has been doing over 50,000 feet of CIPP liner repair with very little inconvenience to City customers. This fiscal year over 65,000 feet will be done.

.