Big Cottonwood Water Treatment Plant Reconstruction Completed

October 8, 1999

|

“Without the cooperation of the consultanting engineer, inspectors and the contractor the outcome could have been different,” exclaimed Hibbert as he addressed those attending the ceremony.

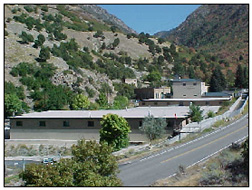

Rick Wheadon, Carollo Engineers, agreed. He likewise noted the combined efforts to construct the project and keep the facility in operation required extraordinary cooperation and coordination. He added that the appearance of the structures added to the utility of the project. “The design goal was to make the treatment facility a good neighbor and fit it into the mountain setting. The sharp box-like edges were given shape and texture, resulting in a much pleasing appearance.” He thanked Mayor Deedee Corradini and the City’s architectural committee for their contribution.

Roger Black, Director of Management Services, representing Mayor Corradini, said that he was impressed with the work. “Clean water is very important. Without it there wouldn’t be a city,” he said. He expressed his appreciation for the work the plant did and the Department’s efforts in protecting the canyon watersheds.

LeRoy W. Hooton, Jr. Director likened this occasion to a similar gathering over 92 years ago when the waters of Big Cottonwood Creek were first diverted into the Big Cottonwood Conduit and sent to Salt Lake City. “Big Cottonwood has significant historic importance,” said Hooton, noting “it provides about 25 percent of the drinking water supply to Salt Lake City and its Salt Lake County service area.” He praised the plant personnel for their exemplary work during construction to still produce high quality drinking water. Further, he thanked Florence Reynolds, Water Quality & Treatment Administrator for her outstanding leadership.

|

The treatment plant is now Y2K compliant. It can be operated on automatic or by manual control. Hibbert is particularly pleased with the ability to monitor the plant’s performance. Turbidity and particle counting monitoring equipment are used to ensure that the finished water far exceeds drinking water standards. By setting a predetermined point, polymers are automatically added when turbidity and/or particle counts reach that point. Particle counts warn of pending filter bed breakthroughs, which results in avoiding turbidity spikes or breakthrough. Plant flow controls keeps the flow through each filter bed at a constant rate during the backwash process. "This prevents turbidity breakthrough," explains Hibbert, "by not having the remaining filters take the extra flow of the filter being backwashed."

Where possible high maintenance items, such as handrails and floors have been replaced with low or no maintenance materials. “Our goal is to be as efficient as possible,” says Hibbert, continuing, “with automation and low maintenance materials we can devote nearly full time to concentrating on treating the water to the highest quality possible.”

To bring the building structures up to seismic standard took engineering skill. Craig Ashcroft, Project Engineer, was acknowledged for his process of replacing the un-reinforced brick walls without removing the roof. His procedure was credited for keeping the plant in operation while the walls were removed and reconstructed with reinforced materials.

The Big Cottonwood Water Treatment Plant just recently received the EPA Partnership Director’s Award for completing Phase 3 of the partnership program. The plant finished water has been consistently below 0.05 NTU's since 1995.

The chemical treatment facility was first put into operation in 1957. The filters were added in 1960. It has been upgraded several times to incorporate new technology and to replace aging and worn out components. In the late 1980s the capacity was increased from 28 million gallons per day to 45 million gallons per day. It can be

|

The cost of treated water from the Big Cottonwood Water Treatment Plant is the lowest cost of all of the department’s surface water sources at $160.48 per million gallons. During FY 1998 - 99 it processed 23,976 acre-feet (7,809 million gallons) of water.

Questions regarding this can be e-mailed to: ken.hibbert@ci.slc.ut.us