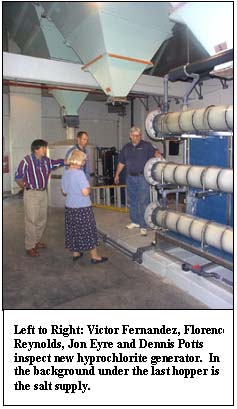

During early May 1999 the Parleys Water Treatment Plant was converted from chlorine gas to liquid sodium hyprochorite as the disinfectant treatment. This change included installing one of the largest sodium hyprochlorite generator units in the United States. Rated at 900 pounds of equivalent chlorine per day, an electrical charge is passed through a salt brine solution to form sodium hydpochlorite with hydrogen gas as a by-product. The hydrogen is vented into the atmosphere and the sodium hypochlorite solution is stored in eleven large tanks for use. The tanks provide a total capacity of 18,000 gallons of 0.8 percent solution (8,200 ppm). This storage alone provides enough disinfection product for two days of full treatment at maximum plant flows. Pumps are used to deliver the hyprochlorite solution into the water to be treated. The hyprochlorite generator is backed up with an electrical on-site generator to ensure operation during power failures. |

|

The new system is capable of producing the product in 300 pound per day increments, to accommodate the flows processed by the water treatment plant. All of the major components are attached to the SCADA system for remote operations.

The Parleys Water Treatment Plant was first put into operation in 1966. Its water source is from the Parleys Canyon drainage, stored in either or both the Little Dell Reservoir and or Mt. Dell Reservoir. Rated at 38 million gallons per day treatment capacity, it is one of three plants owned and operated by Salt Lake City. On average the treatment facility treats and delivers about 15,000 acre-feet of water to the City’s water distribution system.

In May of last year, the City Creek Water Treatment Plant was converted to a salt generator system, and with a year of successful operation, the decision was made to install the same technology at the Parleys treatment facility. Faced with installing a large chlorine scrubber for safety reasons, it was more cost effective to install the hyprochlorite generation system and avert the cost of the scrubber and major renovation of the building.

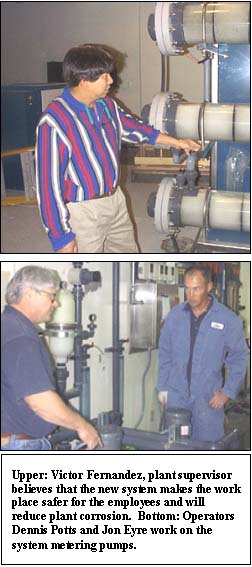

Mr. Victorino M. Fernandez, Plant Supervisor of 10 years, is pleased with the new system, "The danger of gaseous chlorine to plant personnel is always a concern. With the new system, we have removed all of the one-ton chorine containers from the plant." He adds that there is another benefit to the new system, "the hyproclorite stays in solution, reducing the amount of gas being released into the atmosphere. I’m confident that this will reduce much of the corrosion problem we have experienced throughout the treatment plant."

Chlorine (either as chlorine gas or hyprochlorite) has long proven to be an effective disinfectant. There are stronger oxidants, but chlorine is widely used in water treatment to disinfect water and eliminate potential pathogens from the drinking water supply. It has the added benefit of maintaining a residual within the water distribution system to destroy any potential recontamination after the treatment process. Ozone, another effective treatment disinfectant, does not have this benefit. But studies have found that Ozone is more effective than chlorine in killing the Cryptosporidium cyst. Cryptosporidium has been found in Salt Lake City’s raw water sources, but none have ever been found in the finished drinking water. Effective coagulation, sedimentation and filtration remove the cyst from the water. All of Salt Lake City’s plants have completed phase 3 of the "EPA Partnership for Safe Water" program to optimize treatment to ensure the removal of Cryptosporidium from the drinking water supply. Those who object to the chlorine taste in their drinking water can eliminate the taste by placing a container of water in the refrigerator, and drinking from the container, rather than directly from the tap. Remember that the chlorine is there to protect the public from water borne diseases. |

|

Mr. Fernandez has experienced a lot of change during the past decade at the Parleys Water Treatment Facility. A major reconstruction project between 1990 – 1992 increased the treatment capacity of the facility. The EPA Partnership for Safe Water has greatly refined the treatment processes, and now a major change in the disinfection process. He mused, "I’ve seen a lot change since I first walked through the front doors in 1971."

Questions regarding this article can be directed by e-mail to: victor.fernandez@ci.slc.ut.us